Introduction

Starting a business is a very exciting adventure. However, it comes with its share of challenges, particularly in the early stages. ne of the most crucial aspects of building and sustaining a successful business is maintaining a consistent supply of high-quality goods or services. Reliable supply chains are the lifeblood of any business and play a vital role in avoiding financial pitfalls and bankruptcy. For new entrepreneurs, identifying the right suppliers can feel overwhelming. This article is meant to serve as a step-by-step guide to help you discover, evaluate, and build strong partnerships with dependable suppliers and manufacturers.

Image 1: A manufacturer producing microchips, highlighting the complexities of manufacturing products.

Once an entrepreneur has decided on a product to sell—such as for example watches—they must determine how to source that product. One option is to produce it themselves. However, as products become increasingly complex, and since most people lack the expertise or resources to manufacture everything on their own, entrepreneurs often need to find a cost-effective source for their goods. This is where manufacturers play a crucial role.

A manufacturer is a company that converts raw materials into finished products. These products are then sold to consumers, wholesalers, distributors, retailers, or even other manufacturers to create more complex items. Many manufacturers focus on a specific type of product to improve efficiency and reduce costs. For example, you might collaborate with:

- A toy manufacturer for creating toys;

- A electronics manufacturer for creating cameras;

- A food manufacturer for making cookies;

- etc.

Working with multiple suppliers and manufacturers

A key piece of advice for businesses is not to limit yourself to working with just one manufacturer. Partnering with multiple manufacturers can help you diversify your inventory, create a unique product mix, and establish a safety net in case of delays or contract issues. This strategy, known as supplier diversity, is an effective way to mitigate supply chain risks.

A smart approach is to secure two manufacturers: one domestic and one international. The domestic manufacturer can act as a backup, ensuring stock availability and customer satisfaction if issues arise with international orders, such as delays or errors. While domestic suppliers may be more expensive, they offer reliability and quick response times, which can be invaluable during disruptions in your foreign supply chain.

Image 2: A manufacturer specialized in creating watches.

How to find a manufacturer

Now, you’re probably wondering how to find the right manufacturer. Ideally, you want a partner who can deliver high-quality products at a low cost, with minimal shipping times, and with whom you can establish a strong business relationship. Poor-quality or overpriced products can jeopardize your business, potentially leading to financial failure. Similarly, strained relationships with manufacturers can cause significant headaches and, in the worst cases, legal disputes.

This article will now guide you step by step through the entire process of finding the perfect manufacturer for your business needs.

Step 1- Identify all potential suppliers

The first step is to identify and map out all potential manufacturers. To make an informed decision about which manufacturer to choose, you must first research and determine which manufacturers are available and suitable for your needs. Here are the most essential tools to assist you in your search:

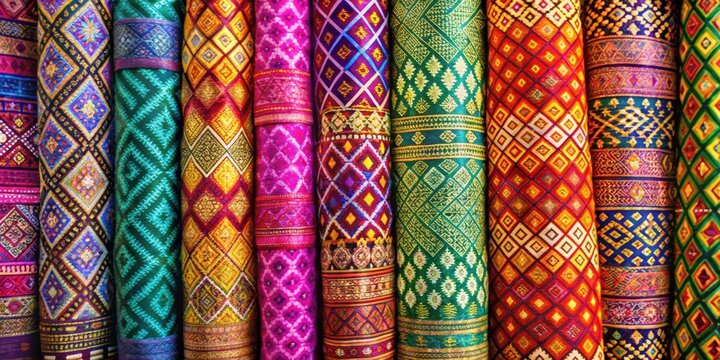

Google: Begin with a straightforward Google search for “manufacturers near me” to identify local options. Examine their websites, customer feedback, and areas of expertise to evaluate their fit for your requirements. You can also search for manufacturers in google maps to see which ones are closest to you.

Image 3: Google maps can be a business owner’s most essential tool.

Helpful tip: Supplier websites are often outdated or lacking in detailed information. Use a variety of search terms, such as ‘wholesale,’ ‘supplier,’ and ‘distributor,’ to expand your search. Additionally, take advantage of Google’s advanced search features to refine and improve your results.

Referrals: One of the most important ways to find potential suppliers is through your network. Don’t hesitate to:

- Seek supplier recommendations from your professional network;

- Connect with successful entrepreneurs in your industry for guidance, and

- Participate in Facebook groups and online e-commerce communities to gather reviews and suggestions.

Suppliers who aren’t a perfect fit may still guide you to the right connections. Industry experts often have access to a network of trusted contacts, so be sure to ask for recommendations when reaching out.

NAICS codes: The North American Industry Classification System (NAICS) assigns specific codes to manufacturers and products, making it easier to find suppliers, particularly in professional directories. Refer to the NAICS codes for the United States and Canada to simplify your search.

Once you’ve shortlisted your options, it’s crucial to conduct a thorough background check on potential manufacturers. Review the Better Business Bureau (BBB) for any complaints and explore customer feedback to confirm their reputation and reliability

Alibaba: Alibaba is a well-known platform that connects you with manufacturers, mainly from China. You can use it to discover existing products or find manufacturers for custom creations. Alibaba is the place most businesses find their manufacturer. You can search for your product there and find potential suppliers. You can filter potential manufacturer by country, price, etc.

Image 4: Alibaba is a great way to connect with suppliers.

When researching manufacturers on Alibaba, look for these qualifications:

- Gold supplier status (they pay for Alibaba membership)

- Verified status (a third-party evaluation services company or Alibaba has visited their facility)

Trade shows bring businesses together to showcase their latest products and services, often taking place over several days in convention centers across major cities. In addition to large-scale events, there are also smaller, regional trade shows that highlight local businesses. These events offer valuable opportunities to experience products in person, connect with business owners, and discover fresh ideas and trends that could inspire new product developments

Trade assurance (free service protecting your orders from payment to delivery)

When looking for manufacturers, consider using filters to identify those with certifications like SA8000, which ensures humane working conditions, if this aligns with your business values. It’s essential to confirm you’re engaging directly with manufacturers, not intermediaries or trading companies, as this can lead to higher costs. Opting for a manufacturer with a track record of at least five years can also help mitigate the risk of financial instability and ensure a more reliable partnership.

Figure 5: Searching manufacturing directories can be a good way to find manufacturers.

Manufacturing directories: Online supplier directories are another valuable resource. These catalogs offer the profiles of thousands of manufacturers, wholesalers, and suppliers. Here are some popular options:

Online domestic (USA) directories:

Online overseas directories:

- AliExpress (Check out our ultimate guide on AliExpress)

- Indiamart

- Sourcify

- Global Sourcing Specialists

- Dun & Bradstreet

Overseas manufacturing, particularly in countries like India, China, and Vietnam, often offers lower costs. According to U.S. News & World Report, these three countries ranked as having the cheapest overseas manufacturing costs. However, consider factors beyond just price when making your decision.

Step 2 – Research your potential manufacturers

Once you’ve identified potential manufacturers, it’s time to request quotes. Aim for at least three quotes to effectively compare your options. For local manufacturers, consider scheduling a tour of their facilities or visiting their office to observe their operations firsthand. This will give you insight into product quality and overall processes. Additionally, explore other manufacturers in the same country that may not be listed online.

Figure 6: It is a pro-tip to travel to to and visit the manufacturer.

Even if the manufacturer is located in another country, such as in Asia, it can still be extremely valuable to visit their operations in person. Traveling to see the facility firsthand allows you to assess product quality, understand the processes, and build relationships with the factory leadership. The leaders of several of the largest fortune 500 companies started off by visiting a factory to find the right products.

An example of this can be Nike founder Phill Knight that started his business by traveling to Japan in his quest for finding the perfect shoe manufacturer.

Beyond pricing, here are key questions to ask:

- Can they handle custom orders? Assess whether they have the skills, resources, and automation features to create your specific product.

- What are their lead times? Ensure they can deliver products quickly enough to keep your customers happy and your inventory stocked.

- What are the shipping costs? Shipping is a significant expense for small businesses.

- What are their minimum order quantities (MOQs)? While it’s best not to lead with this question, you’ll need to know the minimum number of items required for production. Remember, this is often negotiable!! Do not get intimidated if they have a high number of MOQs on their website.

- What’s the cost per unit? Negotiate this alongside MOQs. Generally, larger orders can lead to lower per-unit costs.

- Can they offer exclusivity? If you’re investing in tooling, ensure they won’t allow others to use it. You might also explore territorial, market, or total exclusivity options, or even private label goods.

- Are there setup fees? Some manufacturers charge fees to prepare equipment for your production run.

- What’s their defect policy? Clarify who covers the cost for incorrect or defective items, including shipping and duties.

- Is the manufacturer sustainable and ethical? Inquire about factory conditions and their impact on workers and the environment.

Compare prices: Even if you’ve found a supplier with high-quality products and a strong reputation, it’s important to ensure their prices remain competitive. For startups with limited business experience, comparing prices from different suppliers can help you gauge the average cost of the materials you need. It’s wise to continue this practice even after selecting a supplier to ensure you consistently get the best prices for your products.

Even if you already have a supplier, it’s still smart to regularly compare your supplier’s prices to the prices of their competitors. By doing this, you’ll ensure that you’re always paying the minimum you need to for your supplies, which is an excellent way to cut costs in a small busines

Tips to negotiating effectively is to:

- Understand the reason behind the supplier’s minimum. Is it due to upfront work? Do they prefer larger buyers?

- Use this understanding to propose a compelling counter-offer.

- If a foreign manufacturer: learn about the culture and business traditions in the country before you send them a message/e-mail it will make them respond more positivly.

Many suppliers ask new businesses to pay for full orders upfront, which is important to consider, as inventory costs can be significant for e-commerce businesses. Be sure to inquire about payment terms for future orders as well. However, many reputable manufacturers are open to negotiating these terms. One option is to propose a 50/50 payment split: 50% upfront and 50% upon receiving the shipment. This approach helps balance the risk for both parties.

Figure 7: Communication and negotiation with the manufacturer is an unavoidable part of the process and therefore essential

Suppliers often receive many quote requests, which can result in delayed responses or even ignored emails. If you’re uncertain about your request, consider making a quick phone call or sending a brief email with a single question to clarify before submitting a full inquiry.

When launching your online business, you’ll probably manage communication with manufacturers yourself, using phone, email, or text. For local manufacturers, in-person meetings are also an option. Choose trading companies that are responsive and proactive in working with you. If a potential partner is slow to reply or reluctant to send samples, they might not be the right fit for your business.

Your initial email should be clear and concise, focusing on assessing the potential fit with the supplier. Highlight key details that matter most to suppliers, such as sourcing information.

While it’s important to inquire about pricing for various quantities, avoid bombarding them with too many questions. Keep the message focused on essential information.

Step 3 – Customize and design your product

After your initial discussions with potential manufacturers, it’s time to share your product design. While some manufacturers offer product development services, including prototyping and 3D modeling, these can be expensive. Consider alternative ways to communicate your ideas, such as:

- Sketches

- Written instructions

- Reference photos

Figure 8: Creating a customized design is essential.

If your chosen manufacturer doesn’t offer design services, you can turn to freelancers on platforms like Fiverr or Upwork for professional design work. Consider hiring:

- Industrial designers

- Product designers

- CAD (computer-aided design) specialists

- Consider working with a local designer for prototypes and custom molds, which may be more cost-effective than using a manufacturer.

Private label products involve manufacturers creating a customized version of an existing product just for your business. Depending on the manufacturer and product, you can request unique branding, materials, ingredients, and features to make your product stand out. Customers often favor private labels, and adding your logo is a powerful way to build your brand identity.

Step 4 – Request samples from suppliers and assess their quality.

A business’s reputation depends on the quality of its products. Poor-quality goods from suppliers can harm your reputation when sold. To avoid this, always request a sample before making a large purchase and moving into full production. Once satisfied, date and sign the sample, and keep one or two as control references.

Control samples act as a quality assurance tool to ensure product consistency. For instance, if a shipment arrives with incorrect colors, you can use the control sample to highlight the discrepancy

A sample is typically a single unit of the desired product, allowing you to test its quality. While some suppliers offer free samples, others may require payment.

If a supplier refuses to provide samples, even for a fee, consider working with them on a trial basis. However, proceed with caution and keep a few key considerations in mind.

Start small when testing a new supplier. Instead of filling your entire inventory, purchase a limited quantity—such as a week’s worth of materials rather than a month’s supply. This way, if the supplier doesn’t meet your expectations, you won’t be left with a large stock of low-quality products.

Only consider using a supplier on a trial basis if they appear trustworthy and reliable in other aspects. If their prices are competitive and they have a strong reputation, it’s likely safe to proceed without a sample. However, if you can’t obtain samples and have little information about the supplier, testing them could lead to more issues than benefits..

Step 5 – Place your order

Even after receiving samples, there’s still room to negotiate terms on payment or MOQ. When negotiating: Focus on building a long-term, healthy supplier relationship and consider the manufacturer’s perspective.

Remember, the goal isn’t to exploit your manufacturing partner for the lowest price, but to create a mutually beneficial partnership.Remember, the goal isn’t to exploit your manufacturing partner for the lowest price, but to create a mutually beneficial partnership.

Make sure to hold a high standard and be professional in your contact with the manufacturer as to not seem as an unserious business.

When everything is done, dont forget to place your order.

Important factors to keep in Mind

The impact of quality on pricing

Premium materials, like switching from cotton to cashmere in apparel production, typically come with higher costs. While these materials can enhance a product’s perceived value, they require a larger upfront investment, leading to a longer wait to recover costs through sales.

Figure 9: Silk which is a high-quality product.

Balancing cost savings with product durability

Non-durable products may affect customer satisfaction but can drive repeat business. Durable products, while commanding higher prices, last longer but are more costly to source. Market research can help you understand the importance of durability to your target audience. For example budget-conscious customers may prefer a $5 umbrella that lasts one season while high-income clients may invest in premium, long-lasting items

Identifying hidden costs in manufacturing

The initial quote from your supplier is just a starting point. Be aware of possible extra costs, particularly when working with overseas manufacturers or wholesale suppliers, including:

International shipping, including customs duties and tariffs, currency exchange rates, third-party quality control or inspection checks, rework and defect costs if the original sample isn’t up to standard and expenses for custom molds or machines

Future trends in manufacturing

Personalized production

Mass customization tailors products to individual preferences at scale, unlike mass production. McKinsey research shows companies excelling in personalization generate 40% more revenue than average, a trend also seen in manufacturing.

Manufacturers can fulfill complex customer orders using technologies like 3D printing, robotics, and data analytics. This allows for flexibility and agility in production without excessive costs. As consumer demand for personalized products grows, manufacturers who adapt will gain a competitive advantage.

Increased use of biomanufacturing

Biomanufacturing, also known as bioprocessing or biotechnology manufacturing, utilizes biological systems like cells or microorganisms to produce products such as pharmaceuticals, biofuels, food, and cosmetics.

The main benefit of biomanufacturing is its sustainability. Biomanufacturing is sustainable, using renewable resources instead of fossil fuels and generating fewer emissions. It also enables the production of complex molecules and materials that traditional methods can’t synthesize.

This manufacturing method will be especially important in fast-paced industries with fluctuating demand or evolving product needs. The biomanufacturing market is already growing, expected to reach over $85 billion, up from $18 billion in 2020.

Figure 10: A company using biomanufacturing as an alternative way to produce products.

Servitization

Servitization enables manufacturers to boost revenue by offering services alongside traditional manufacturing. These can include aftermarket goods, maintenance services, training, and customer support agreements.

By embracing servitization, manufacturers can foster stronger, more profitable customer relationships and create new recurring revenue streams. This trend is especially relevant in industries with long product life cycles, like machinery, equipment, and vehicles

Smart Factories

A recent Deloitte survey highlights smart factories as a key priority for manufacturers in 2024. Amid rising costs and economic uncertainty, 83% of manufacturers believe smart factory solutions will transform production in the next five years. These factories use IoT, AI, and machine learning to optimize processes, reduce downtime, and improve efficiency. As competition grows, smart factories are likely to become the industry standard.

Figure 11: The use of AI for manufacturing is a trend that will continue.

Social Media

Mastering social media has become essential for businesses, as it offers a powerful tool for reaching and engaging with potential customers. Online influencers, using platforms beyond just LinkedIn and blogs, can recommend specific vendors to their audience, driving traffic and sales. This is often done through links to eCommerce websites or stores on platforms like Shopify.

Influencers can be compensated in two main ways: they may receive upfront payment as partners of the sponsoring vendor or earn commissions as affiliates for each purchase made through their referral links. This strategy allows businesses to tap into the influencer’s network, boosting visibility and sales, especially in a digital-first world.

tlovertonet

Hello, Neat post. There’s a problem with your site in web explorer, may test this?K IE nonetheless is the market leader and a large section of people will miss your magnificent writing due to this problem.